1990

The trend

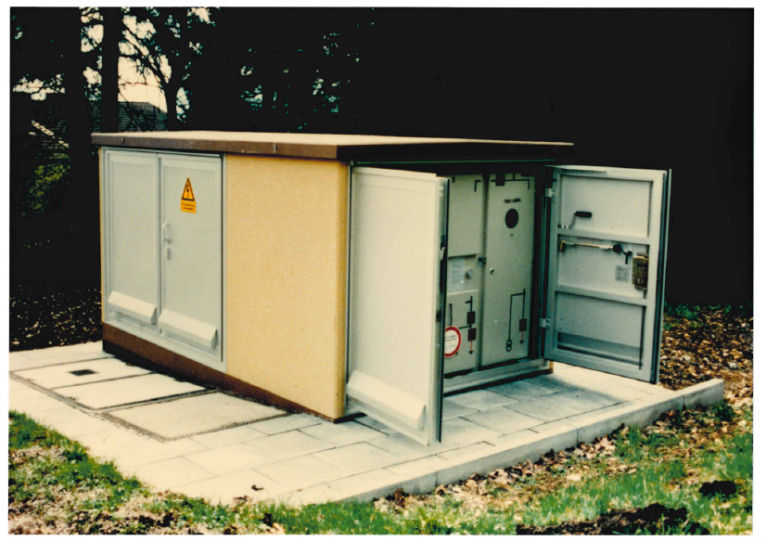

towards prefabricated stations, which Betonbau set early on, has arrived on the

mass market and has become the standard.

Construction

site times can be reduced from months to days thanks to factory-finished

stations, so that usually only the excavation pit has to be dug and the

external cables laid and connected.

+ Milestones:

Systematic research into the thermal behavior of stations and the influence of ventilation geometries. The knowledge gained as part of close university cooperation with the University of Karlsruhe (now KIT) and the TU Dresden leads to numerous publications and takes the development of concrete construction thermal management systems to the next level.

The doors and ventilation systems are continuously developed on the basis of these findings, among other things, up to the third generation, which is still in use today, such as the TAM3.

The introduction of the first international standard for prefabricated substations (IEC 61330:1995 and VDE 0670-611:1997) marked an important milestone for network operators and manufacturers alike.

Gas-insulated switchgear is becoming more reliable and cheaper and is being used more and more frequently. This makes even smaller station sizes possible.

+ Advantages:

Aluminum does not rust: Innovative customers appreciate the new generation of aluminum door and ventilation elements for their durability, good recyclability and stability.

The new optimized frames and the internal hinges of the new TAM3 doors not only look good, but also reduce points of attack for vandalism and burglars. The research and wind tunnel studies are also paying off: the new generation of fans reduces the flow resistance, allowing the stations to be cooled more effectively and increasing their service life.