COMPACT TRANSFORMER STATIONS

Substations with external service

GRITEC compact transformer stations represent an ideal solution for situations where an uncluttered, unobtrusive design is desirable in public places or where only limited usable space exists. They feature very modest height and a minimum footprint. They are a non walk-in design, accessible from outside for the operating personnel. As a rule, 630kVA transformers are used to fit these stations, and up to 2.5MVA for special projects.

SUMMARY DESCRIPTION AND COMPARISON WITH THE WALK-IN STATIONS

| STATION TYPE AND CODE | COMPACT | WALK-IN |

|---|---|---|

| GRITEC model series code | UK | UF |

| Operator access | non walk-in | walk-in |

| Height from ground | approx. 1.5m, less than 1m for underground (or, half-buried) stations | approx. 2.8 m |

| Footprint | approx. 3–6 m2 | approx. 6–25 m2 |

| Weight, equipment exclusive | 7–13 t | 13–50 t |

| Transport | common road truck | oversize load |

| Transformer output power | normally 630kVA, up to 2.5MVA depending on project | up to 4.8MVA, or more depending on project |

| Transformer placed on | transformer station floor | rails |

| Transformer replacement | following roof dismantling | through door |

| HV switchgears | common compact design, insulated with SF6 gas, air or vacuum | insulated with SF6 gas or air, up to 38kV, both compact and modular |

ELECTRICAL TECHNOLOGIES

All compact stations are as standard prepared for installation of transformers up to 630kVA (inclusive). We examine case by case special projects for transformers up to 2.5MVA, their ventilation dimensioning being a key focus.

The transformer space is set up as an oil retention pit and, given the watertight and oiltight features of the applied concrete, it provides the required level of environmental protection, without any additional waterproof coatings necessary.

In most cases, we install compact, SF6 gas insulated HV switchgears in the compact transformer

stations. For individual projects, we may apply air

switchgears and an HV measurement field.

The LV switchgears from various manufacturers are adjusted to the limited dimensions of the transformer station space. A consumption and balancing meter may be also mounted to take official or indicative readouts

The integrated cable compartment of the station serves also as the station base.

Robust, patented cable grommets are placed in the underground part of the station and serve as pass-throughs for all standardised cables used in the power engineering industry.

Compact transformer stations may be operated

from four, three, two or just one side.

GRITEC CONCRETE PRODUCTS

The body of a station is comprised of 4 external, 10cm thick walls and a 12cm thick bottom. We precast the body using the “bell casting” method, as a single seamless casting. The manufacturing method gives the following features to the body:

- exceptional mechanical resistance. The body is a self-supporting box type element and, as a result, the single cell needs no rigid foundation. We lay it upon the ballast bed as is standard,

- perfect tightness; the cast-in-place, seamless concrete body is watertight, serving at the same time as an impermeable pit to catch oil in case of a transformer accident,

- easy transportability, based again on the mechanical stability of the body itself,

- long service life and reliability.

We make the body, roof and partition walls from impermeable concrete of C35/45 strength class and XC4 and XF1 exposure classes compliant to ČSN EN 206-1.

The roof is executed as a separate roof slab with

a 2% slope. A loose laid arrangement is applied within

the station, with the conductive interconnection supported by massive hot-dip galvanised angles. Such

execution provides for the easy dismantling of the roof

and technology installation, or as the case may be, replacement in future years.

The partition walls are 8cm thick and may be reduced to fit the doorsill height.

The false floor is executed either from concrete or using an extruded aluminium shape system. The concrete raised floor is fire safe, while the aluminium shape system offers a high degree of flexibility. We mount the aluminium shapes on the adjustable galvanised steel supports. The tread layer is of plywood with self-extinguishing surface treatment. The floor panels are fitted with a key operated latch preventing their accidental lifting.

IRONMONGERY PRODUCTS

We make the doors and ventilation elements from anodized aluminium in our in-house METALLBAU machine shop. The material is corrosion resistant and its durability is on a par with that of the concrete used for the construction body.

COMPACT TRANSFORMER STATION TYPES AND DIMENSIONS

| COMPACT TRANSFORMER STATION | EXTERNAL WIDTH (m) | EXTERNAL LENGTH (m) | HEIGHT FROM GROUND (m) | TOTAL HEIGHT (m) |

|---|---|---|---|---|

| UK 1250-20 | 1,45 | 2,03 | 1,56 | 2,22 |

| UK 1250-25 | 1,45 | 2,51 | 1,56 | 2,22 |

| UK 1250-34 | 1,45 | 3,44 | 1,56 | 2,22 |

| UK 1250-36 | 1,45 | 3,60 | 1,56 | 2,22 |

| UK 1700-15 | 1,90 | 1,58 | 1,65 | 2,40 |

| UK 1700-23 | 1,90 | 2,30 | 1,65 | 2,40 |

| UK 1700-28 | 1,90 | 2,80 | 1,65 | 2,40 |

| UK 1700-42 | 1,90 | 4,21 | 1,65 | 2,40 |

| UK 2536 | 2,50 | 3,58 | 1,685 | 2,565 |

| UK 2548 | 2,50 | 4,78 | 1,685 | 2,565 |

| UK 3015 | 3,00 | 1,50 | 1,64 | 2,39 |

| UK 3024 | 3,00 | 2,38 | 1,68 | 2,56 |

| UK 3048 | 3,00 | 4,78 | 1,685 | 2,565 |

| UKL 3119 | 3,15 | 1,92 | 1,695 | 2,395 |

IMPLEMENTATION

For the sake of accelerating construction works, we

install the electrical technologies in the station already

at the production plant.

Self-standing stations are placed on a prepared ballast course without foundations.

We haul compact stations by common road trucks

and use a crane to place them. The weight, equipment

exclusive, ranges from 7 to 13t.

The engineering structure user provides for the base

course preparation and for external cabling and earthing execution.

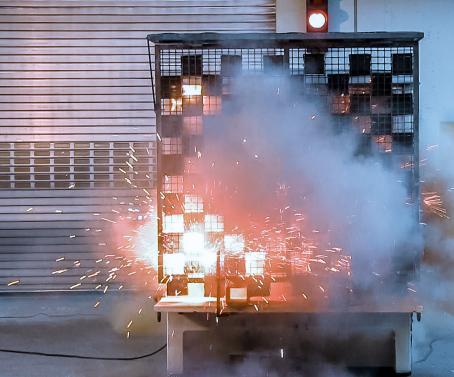

SAFETY

Our priority is to protect health and assets. Our products conform to all requirements placed on them by the standards and regulations. Thanks to our innovative solutions, we stand ready to provide even stronger protection and safety levels upon request.

CONFIGURATION OPTIONS

We are committed to providing you with an option to modify the appearance of the technical buildings as part of the implementation process.

OPERATIONAL AND SUPPORT SERVICES

We offer comprehensive support services with our transformer stations at maintenance, rehabilitation and modernisation.

We will find the optimal solution for your project. Ask our sales and technical representatives for advice or a no-obligation price offer.